Koporo

Koporo

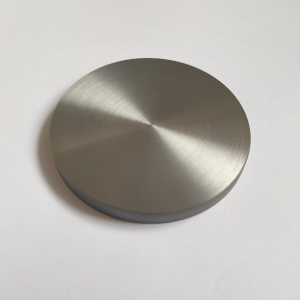

Koporo e na le boima ba athomo ba 63.546, boima ba 8.92g/cm³, ntlha e qhibilihang ke 1083.4±0.2℃, ntlha e belang 2567℃.E 'mala o mosehla o mofubelu ka chebahalo ea 'mele 'me ha e bentšitsoe e hlahisa khanya e khanyang ea tšepe.Koporo e na le ho tiea ho hoholo ka mokhoa o hlakileng, khanyetso ea ho roala, ductility e khotsofatsang, ho hanyetsa kutu, motlakase le mocheso oa mocheso.sebetsa ka mefuta e sa tšoaneng ea lisebelisoa.Li-alloys tsa koporo li na le thepa e ntle ea mochini le ho hanyetsa ho fokolang, lisebelisoa tse ka sehloohong tsa koporo li kenyelletsa li-brasses (li-alloys tsa koporo / zinki) le li-bronzes (li-alloys tsa koporo / tin tse kenyeletsang li-bronze tse nang le lead le phosphor bronzes).Ntle le moo, Copper ke tšepe e tšoarellang hobane e loketse haholo ho e sebelisa hape.

Koporo e phahameng e ka sebelisoa e le lisebelisoa tsa ho beha lithapo tsa phetisetso ea matla, likhoele tsa motlakase, likhoele le libare, potoloho e kholo e kopaneng, le lipontšo tsa phanele tse bataletseng.

Tlhahlobo ea Tšilafalo

| Purity | Ag | Fe | Cd | Al | Sn | Ni | S | Kakaretso |

| 4N(ppm) | 10 | 0.1 | <0.01 | 0.21 | 0.1 | 0.36 | 3.9 | 0.005 |

| 5N(ppm) | 0.02 | 0.02 | <0.01 | 0.002 | <0.005 | 0.001 | 0.02 | 0.1 |

Rich Special Materials ke Moetsi oa Sputtering Target mme a ka hlahisa Lisebelisoa tsa Copper Sputtering ka bohloeki ho fihla ho 6N ho latela litlhaloso tsa Bareki.Ho fumana lintlha tse ling, ka kopo ikopanye le rona.